Mixing Profiling

With Intelligent Tomography for Pipelines and Vessels

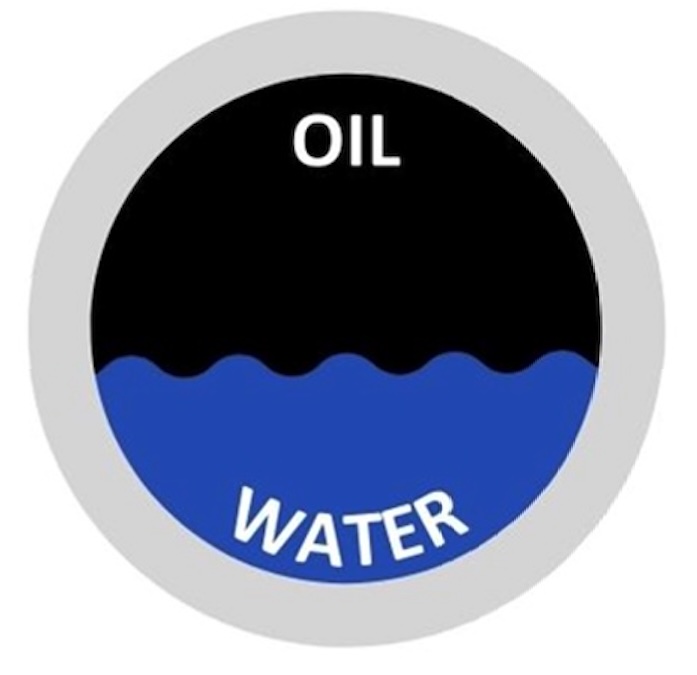

Mixing Profiling is a Solution for Assessing Vertical Mixing Conditions in any Pipe or Vessel — Especially in Oil and Gas Trunk Lines — To Optimise Chemical Dosing and Process Efficiency

Benefits

- Works with any media. Especially with high temperatures and pressures and depositing conditions

- Extremely easy to install (ask sales for more details). Justa. cable conductor is needed.

- Robust - Can withstand any pressure and temperature needed

- Can be used in any chemical environment based on material selections

- Uses Intelligent Tomography Platform providing maximum value from the process data

- Hermetically sealed - meaning nothing goes inside and the sensor is long lasting

The IntelligentTomography is PREDIT's proprietary technology designed to inspect areas outside the capsule boundary

At PREDIT, we use Intelligent Tomography — A revolutionary concept that maximizes the value of process data by combining advanced tomographic methods with AI and proprietary signal processing. This approach enables deep understanding of process fluids, emulsions, foams, and gases — all within the sensor boundary — using as few as two to eight electrodes.

Ultrasound

Tomography

Mixing Profiling is a clamp-on tool designed to measure the condition of any pipe, regardless of its condition.

Materials

The sensor can be manufactured into any machinable material Standard combination are

The sensor can be manufactured into any machinable material Standard combination are

Stainless Steel 316L / Titanium Gr2 + UHMWPE - 8 bar (116 psi), 70 °C (158 °F)

Stainless Steel 316L / Titanium Gr2+ PEEK - 64 bar (928 psi), 90 °C (194 °F)

Stainless Steel 316L / Titanium Gr2+ PPS GF30 - 96 bar (1392 psi), 120 °C (248 °F)

Stainless Steel 316L / Titanium Gr2+ PEEK GF30 - 128 bar (1856 psi), 150 °C (302 °F)

Stainless Steel 316L / Titanium Gr2+ Ceramics - 300 bar (4351 psi), 500 °C (932 °F)

Power

The system supports flexible power options:

– 17–36 VDC (2.5 A, 2-wire) for wired setups

– 18 V / 5 A battery for mobile or remote applications

For pilot testing, battery power further simplifies installation and enables use in remote or hard-to-access locations.

Battery life varies by usage but typically lasts up to one year. The system has an ultra-low standby current of 1 µA and can be remotely activated via the LoRaWAN network.

Electronics & Mechanics — Engineered for Demanding Industrial Environments

Our electronics are designed and built in-house by PREDIT, ensuring maximum performance and reliability across all applications.

For the mechanical interface, choose between MiniCapsule, ClampOn, or InTouch — each optimized for specific installation needs.

Our team will guide you to the most effective option for your process.

IoT + Connectivity

Multiple systems can be networked and connected to a cloud service via a LoRaWAN connectivity network, significantly reducing the need for traditional automation wiring and making a fast start.

For fixed installations, we offer standard integration interfaces such as 4–20 mA, Modbus TCP/IP, ask for more.